Equipment Fleet

Only a constantly updated machine fleet allows us to optimize production processes.

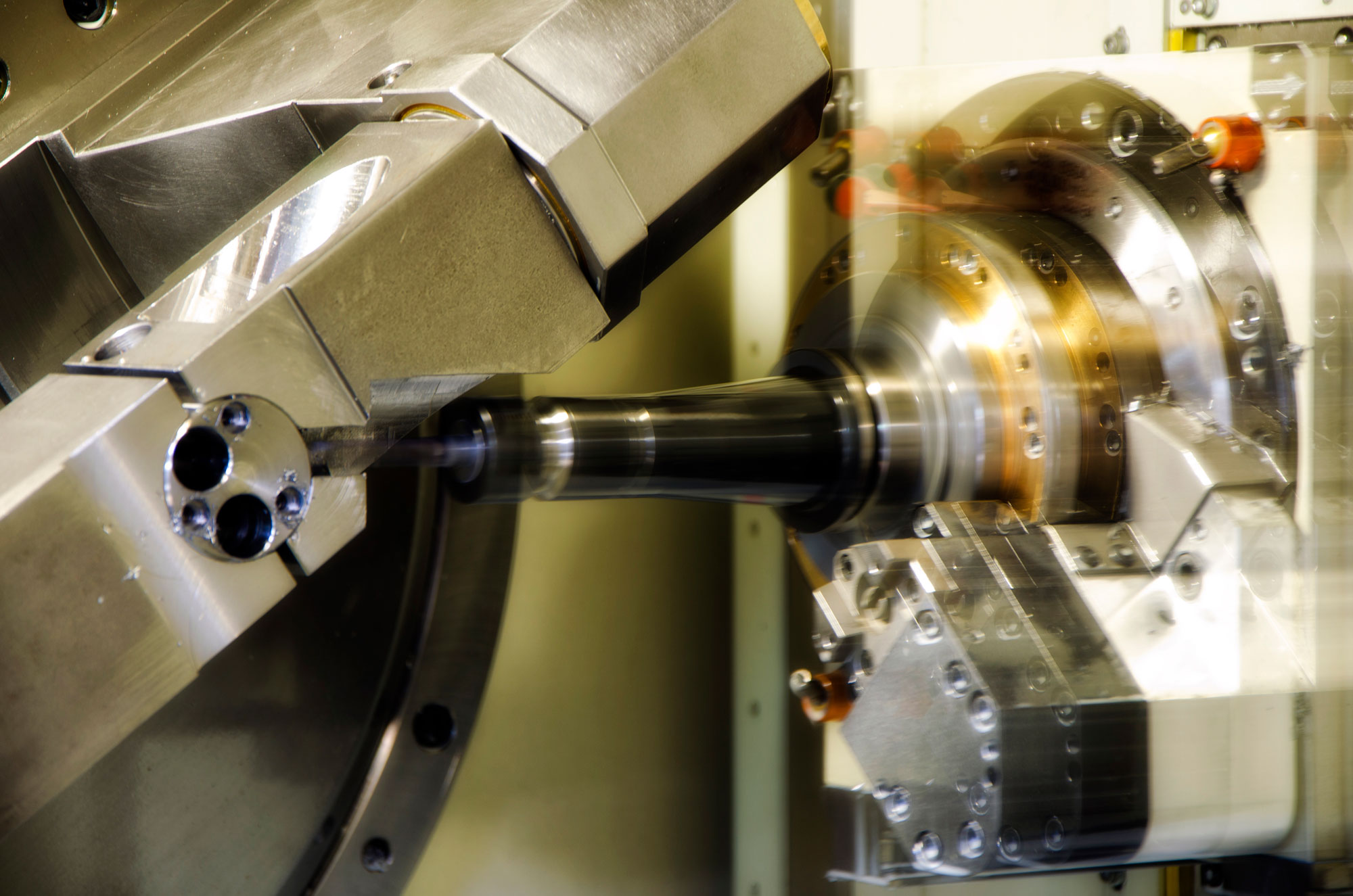

We head to the Highest Precision.

From small batches to large orders, we meet customer needs through turning centers, working centers, automated transfer machines, and fast, flexible, multifunctional automatic machines. We handle bar machining, stamped parts, and die-cast components.

Turning Centers

With our dual-spindle lathes equipped with 2-3-4 motorized turrets and up to 4 Y-axes, even with a movable tailstock, we can perform bar machining with a max Ø of 75 mm and up to Ø 200 with automatic loading via integrated gantry, or Ø 320 with manual loading.

Horizontal and Vertical 5-Axis Machining Centers

With our vertical or horizontal machining centers, we can carry out 5-axis milling operations (4 in continuous) with manual loading or automation using robots and vision systems.

Transfer Machines

With our CNC and traditional transfer machines, we can perform machining on stamped parts or die-castings in stainless steel, brass, and aluminum for medium to large batches.

Sawing Machines

For cutting parts obtained from bars, we use automatic saws with a capacity of up to Ø 360.

POR funding – Objective

“INVESTMENTS FOR GROWTH AND EMPLOYMENT”

Unic was once a traditional turning company, but it quickly evolved into something different. A space dedicated to innovation, to the development of solutions, and the research for the perfect balance in every process: reducing time and costs while maintaining excellent quality is possible for us. And we know how to do it.

Request Information

Fill out the form, and our expert technicians will analyze your request. We will get back to you as soon as possible!